Table Of Content

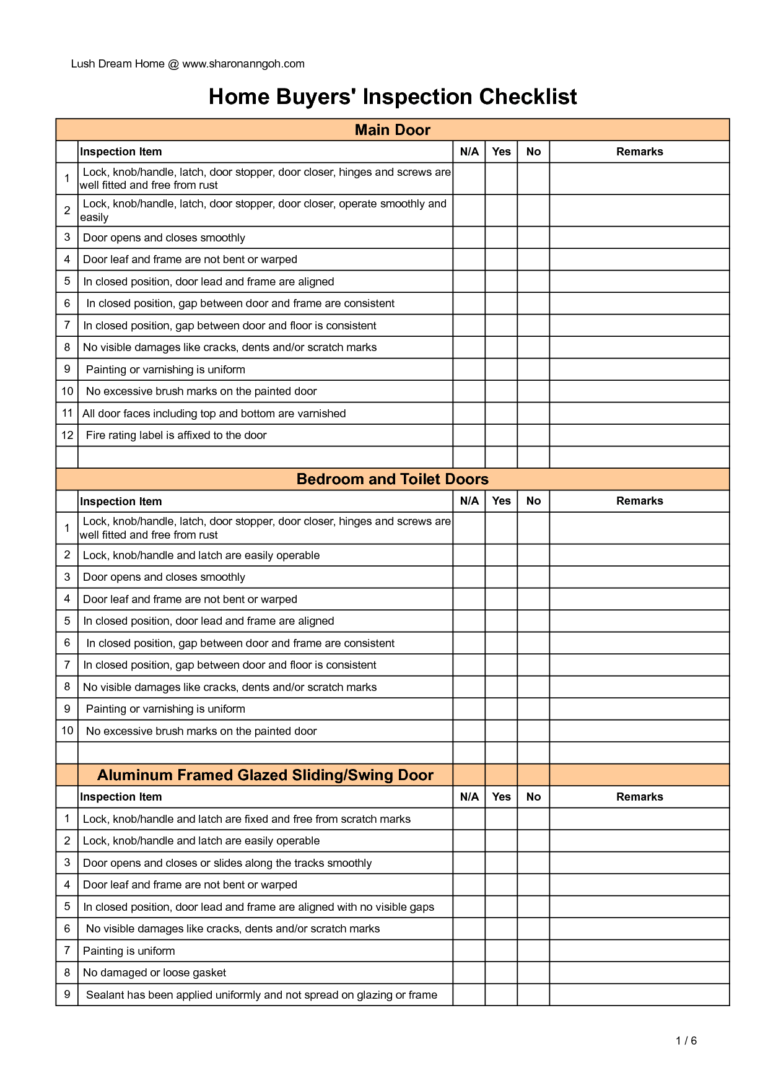

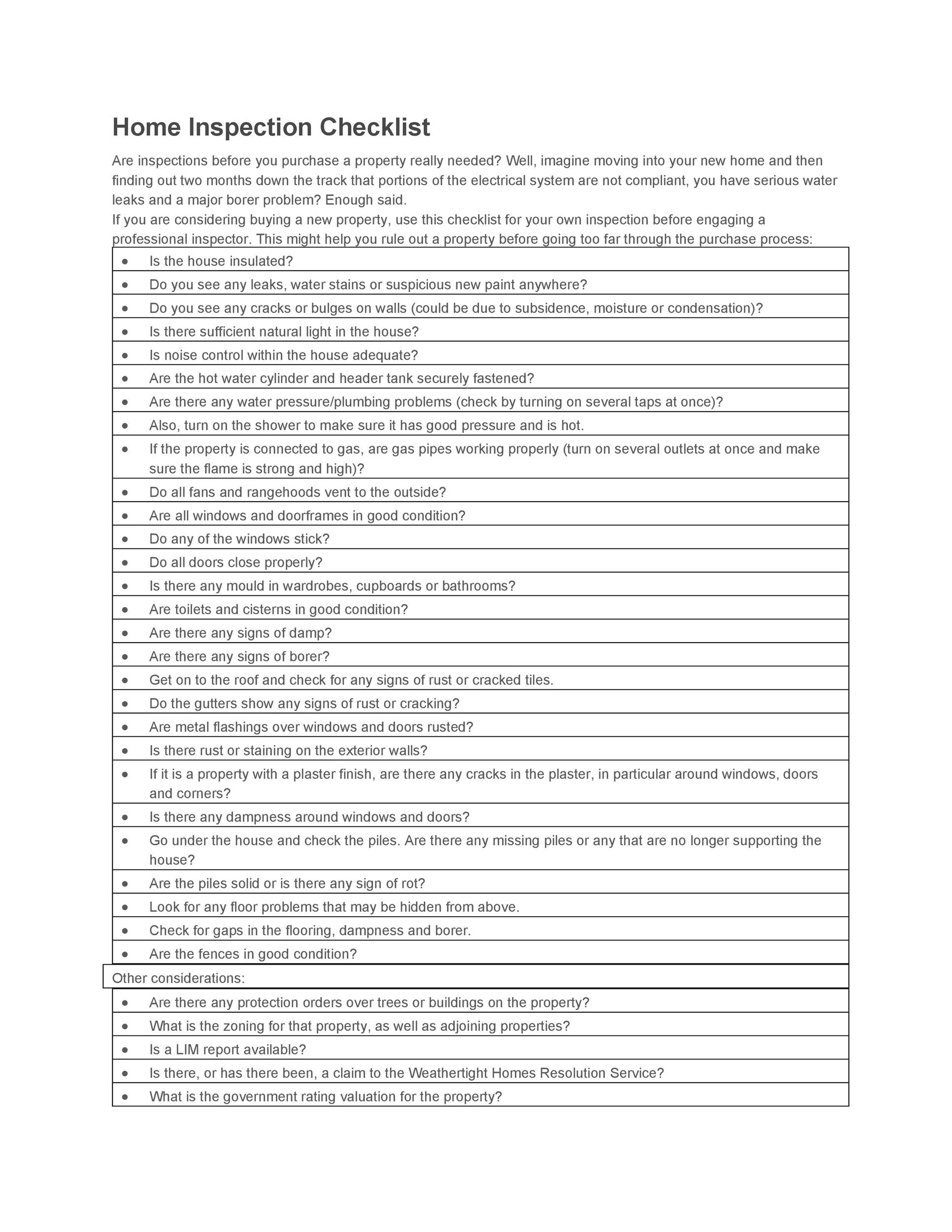

Major contour changes can invoke pressure drops, resulting in less air (or fuel) entering the combustion chamber. Designing a manifold involves considering various factors such as intake manifold design parameters, intake manifold design techniques, and intake manifold design considerations. It is important to optimize the design for intake manifold performance, airflow, and pressure drop. Simulation and analysis can be used to refine the design, and optimization techniques can be employed to achieve the desired results. Another crucial factor in intake manifold design is minimizing pressure drop.

What are the different types of intake manifold runner designs?

Here is the finished engine utilizing the induction system on page 38— 402 ft-lbs and 443 hp from a totally street-drivable 302. The material for the plenum was something I thought would be trivial since any metal should be better than the thin plastic. But Andreas from PPF warned me that in his experience if you use less than 4mm thick aluminum the plenum will eventually crack – plastic might be weaker but it doesn’t fatigue the way metal does. This page from Scientific Design of Intake and Exhaust Systems, by Philip H Smith and John C Morrison, gives an idea of how drastically runner length affects the amount and timing of peak torque. The engine simulations were carried out using CONVERE v2.4 as the three-dimensional CFD program.

How does the intake manifold affect your engine?

The throttle body, which mounts on the front, feeds a plenum in very much the same manner as a tunnel ram. The fact that all eight barrels of carburetion, each of relatively large CFM, can be seen by any individual cylinder means the plenum runs at barely below atmospheric pressure. The absence of a butterfly within the runner also means that the runner is uncompromised both in terms of airflow and pressure-wave reflection. This makes the tunnel ram the number-one power producer when it comes to manifolds for normally aspirated engines. Because these modern intakes have so much more airflow capability than earlier designs, it has become necessary to reevaluate just how much carburetion they need for optimal results.

Length and Volume

They may be able to offer you valuable advice about what other components can be used to optimize your engine’s performance. The intake manifold is typically located on top of the engine, between the throttle body and the cylinder head(s). In most engines, it is positioned on the side or top of the engine block, allowing easy access for air intake.

How to Port and Polish Intake Manifold

Performance Design Carbon pTR Intake Manifold - Engine Builder

Performance Design Carbon pTR Intake Manifold.

Posted: Fri, 13 Aug 2021 07:00:00 GMT [source]

In V6 intake manifold design, the focus is on achieving a balanced air flow distribution to all cylinders. This is typically achieved through careful design of the plenum chamber, which acts as a reservoir for the incoming air. By ensuring equal air distribution to each intake runner, engine performance can be maximized. Additionally, the shape and taper of the intake runners can also be optimized to enhance air flow velocity and improve overall engine efficiency. The intake manifold is a crucial component in an engine’s air intake system. It plays a vital role in delivering the air-fuel mixture to the combustion chambers for efficient combustion.

Thus, the simulation results of stream-lines that were conducted under the same condition of the experiment were compared with the Mie-scattering image using fog. As a result of validation of the intake manifold flow, the flow travel distance and distribution in the intake manifold showed similar results with various intake throttle valve opening angles (Fig. 10). An additional grid embedding was set in the in-cylinder region to refine grid to 2.0 mm, in in-cylinder boundary to 1.0 mm, and in the valve and intake port boundary to 0.5 mm. Adaptive mesh refinement with the embedding level of 2 was used to generate more refined cells where the velocity difference between cells higher than 2.5 m/s.

These materials offer a combination of strength, lightness, and heat resistance. So, whether you are a seasoned car enthusiast or a beginner looking to enhance your vehicle’s performance, customizing and upgrading the intake manifold can be a rewarding endeavor. By understanding the design considerations, benefits, and compatible options, you can make informed decisions to unleash the full potential of your engine. Remember, modifying the intake manifold without proper knowledge and expertise can have adverse effects on engine performance and reliability.

Designing an Engine Intake Manifold

This is because the improved airflow allows for more efficient combustion, resulting in increased power output. An intake manifold works by receiving the air/fuel mixture from the throttle body and distributing it evenly to each cylinder’s intake ports. It ensures that the right amount of mixture is delivered to optimize combustion and power output.

Pressure drop refers to the decrease in air pressure as it flows through the intake manifold. By carefully selecting materials and optimizing the internal geometry, engineers can minimize pressure drop and ensure smooth airflow. Figure 27 represents the volumetric efficiency for different intake curve radius and cylinders. In cylinder 1 without a swirl valve in the inner port, the volumetric efficiency increased by 0.5% as the intake manifold cure radius increased from 7 to 10 cm at engine speed of 2000 rpm. However, there was no significant difference in the volumetric efficiency for different intake curve radius under other conditions.

Additionally, if you are performing any maintenance work on the intake manifold, it is recommended to replace the gasket as a preventive measure. Designing an efficient intake manifold involves various calculations and considerations. One important calculation is the determination of the intake manifold runner length. The runner length affects the engine’s torque characteristics at different RPM ranges.

It is important to select a gasket material that can withstand the specific demands of the engine to ensure optimal performance and reliability. Since most of us aren’t planning on building an intake manifold from scratch, we must depend on the high- performance intake manifold manufacturer to get it right. As we have already mentioned, just because a certain intake manifold looks bigger and better and bolts to the cylinder head doesn’t mean that it will offer improved performance. The same aftermarket intake manifold that optimizes performance on a near-stock engine may not be the ideal choice if engine displacement and redline have been increased. Let them know about your engine combination, your intended use and your future performance improvements.